+86 18101795790

+86 18101795790

Contact:Gensors

Phone:+86 18101795790

TEL:+86 021-67733633

Email:sales@bmbond.com

Address:22, Lane 123 Shenmei Road Pudong New District Shanghai, China

The pressure scanning valve stands as a pivotal innovation, marking wind tunnel testing's transition from a "manual

era" to a modern, digital age. By delivering massive volumes of synchronized, high-precision pressure data, it

enables engineers to understand complex flow phenomena with unprecedented completeness, fidelity, and

efficiency. This provides indispensable data support for optimizing the safety and performance of aircraft,

automobiles, and other products.

1. Why are Pressure Scanning Valves Used in Wind Tunnel Tests?

A core objective of wind tunnel testing is measuring the surface pressure distribution on a model (like an aircraft

wing or car body) as air flows over it. This data is crucial for:

Calculating key aerodynamic parameters like lift, drag, and moment.

Identifying flow phenomena such as flow separation, shock wave locations, and vortex structures.

Before pressure scanning valves, engineers relied on:

Single-Point Measurement: One tube connected to a mechanical manometer (e.g., a U-tube), measuring just one

point per test.

Mechanical Scanivalves: A rotary valve manually switched between multiple pressure ports, allowing sequential

measurement of multiple points but at very slow speeds without simultaneous data capture.

These traditional methods had major flaws:

Lack of Synchronization: Inability to record pressures at all points simultaneously. Since the flow field is dynamic

and highly interconnected, non-synchronous data introduced errors and failed to capture the true transient state.

Extremely Low Efficiency: Measuring hundreds or thousands of points could take days or even weeks, incurring

enormous costs for tunnel operation, equipment, and personnel.

The pressure scanning valve perfectly solves these problems. It is a highly integrated electronic multi-channel

pressure acquisition system. Its core is a precision motor-driven valve that rapidly, automatically, and sequentially

switches between dozens or even hundreds of pressure channels. A high-precision sensor then converts the

pressure from each channel into an electrical signal.

Key reasons for its use are:

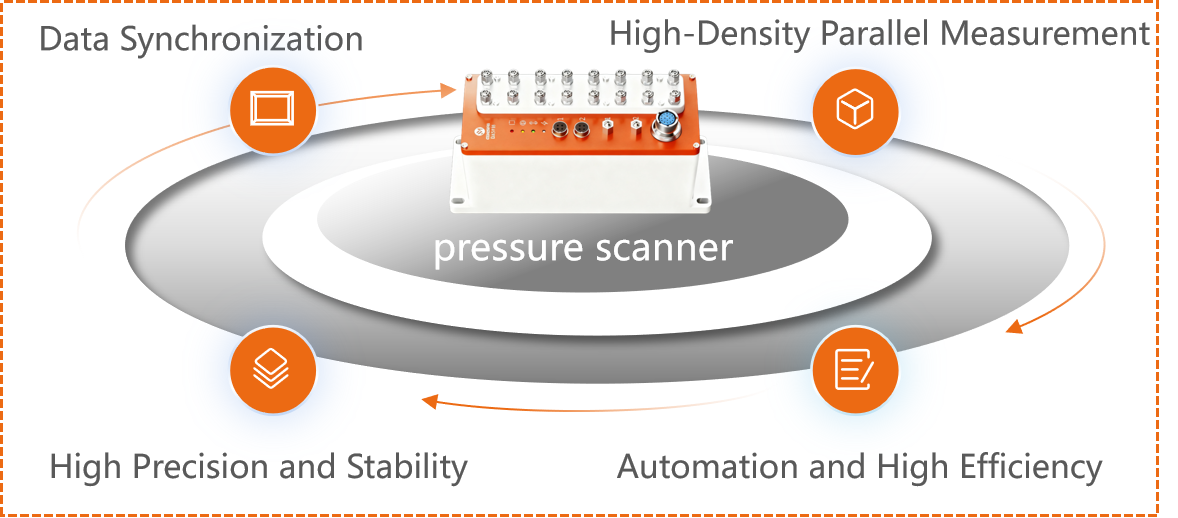

High-Density Parallel Measurement: A single scanner can integrate 64, 128, or more sensors, allowing for extremely

dense arrays of pressure taps on a model surface.

Data Synchronization: Although channels are scanned sequentially, the switching speed is extremely high (thousands

of samples per second). The time to scan all channels is minimal (milliseconds), approximating synchronous

measurement and capturing the instantaneous state of the flow.

High Accuracy and Stability: Built-in, precision-calibrated sensors offer greater accuracy and reliability than

traditional mechanical methods.

Automation and High Efficiency: Integration with computer systems enables fully automated data acquisition.

Measurements that once took days can now be completed in minutes, drastically reducing test duration and cost.

2. How is a Pressure Scanning Valve Used?

The workflow can be summarized as follows:

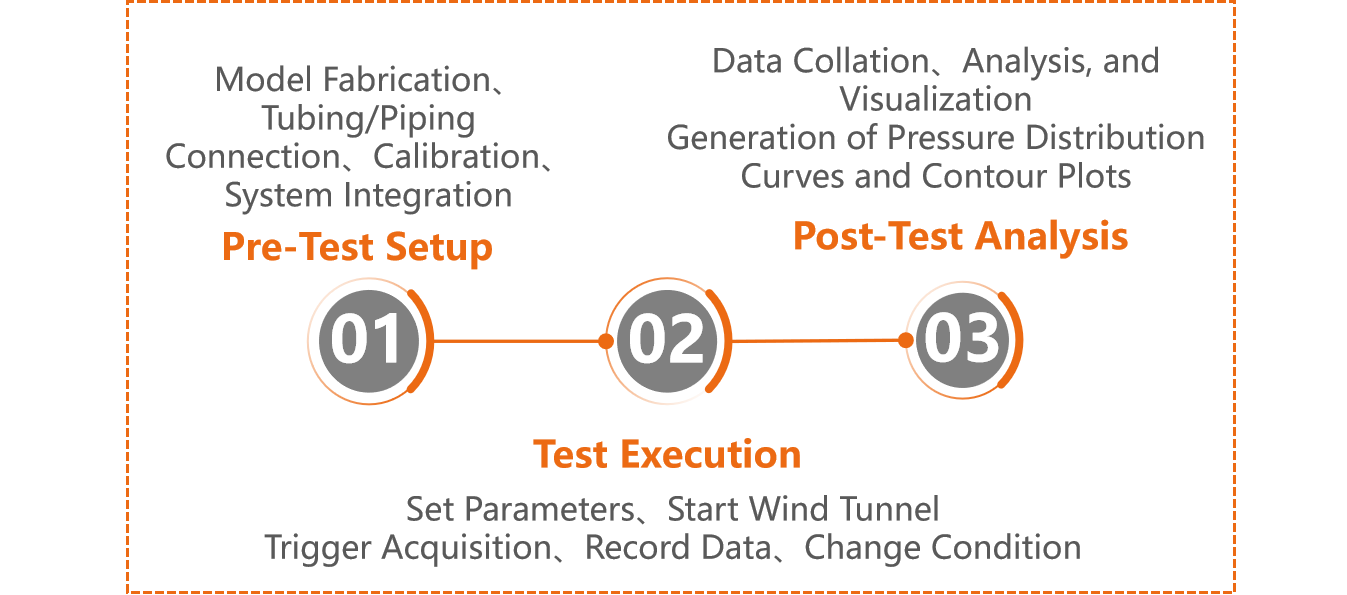

A. Pre-Test Preparation:

Model Fabrication: Numerous tiny pressure taps are drilled at carefully designed locations on the wind tunnel model.

Tubing Connection: Small tubes connect each pressure tap to a corresponding port on the scanning valve.

Calibration: A critical step. A highly accurate standard pressure source is used to calibrate each channel, establishing

a precise relationship between the electrical signal (e.g., voltage) and the physical pressure (e.g., Pascals).

System Integration: The scanner's output is connected to a Data Acquisition system (DAQ) and a control computer.

B. During the Test:

Parameter Setting: Sampling frequency, duration, and active channels are set in the control software.

Tunnel Start: The wind tunnel runs until the airflow stabilizes at the desired speed (Mach number) and angle of attack.

Trigger & Acquisition: Upon stabilization, the operator triggers the system. The scanner's core valve rotates rapidly,

sequentially connecting each pressure port to the central sensor.

Data Recording: The sensor measures each pressure, sending signals to the DAQ and computer, where software

converts them to pressure values in real-time and stores them.

Condition Change: The test condition (e.g., angle of attack, speed) is changed, and the acquisition process is repeated.

C. Post-Test Processing:

Software analyzes the massive pressure datasets, generating visualizations like pressure distribution plots and

cloud maps.

3. How Does the Test Data Benefit the Experiment?

The acquired pressure data is a "gold mine":

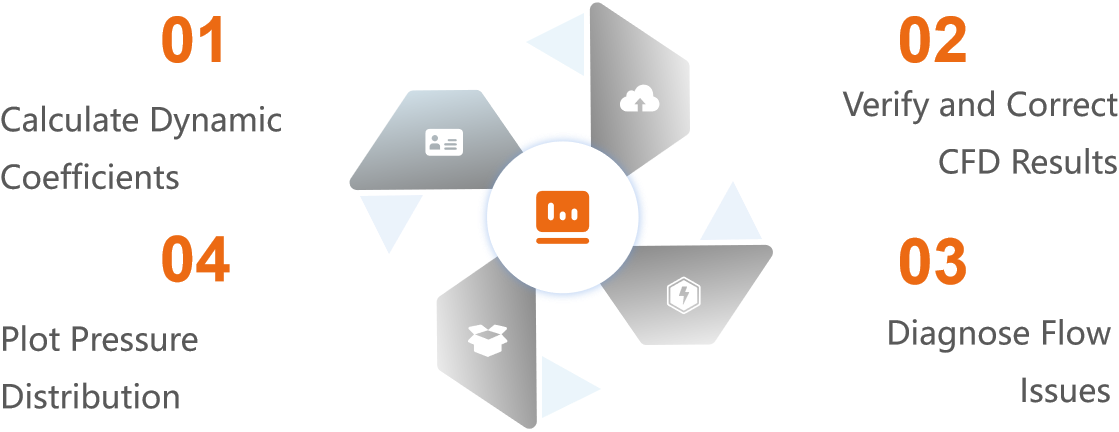

Calculating Aerodynamic Coefficients: By integrating surface pressures, engineers precisely calculate the overall

lift, drag, and pitching moment coefficients, providing the most direct basis for performance evaluation.

Mapping Pressure Distribution: Data is plotted as pressure coefficient curves across the model surface. These plots

reveal key features: the stagnation point (highest pressure), suction peak (lowest pressure, crucial for lift), shock

waves (sudden pressure rises), and flow separation.

Validating CFD Simulations: Data from scanning valves serves as the "gold standard" for verifying and refining

Computational Fluid Dynamics models.

Diagnosing Flow Issues: Pressure maps instantly reveal design flaws, such as unexpected low-pressure regions

or separation bubbles, helping engineers quickly identify root causes.

4. How Does it Ultimately Enhance Test Completeness?

Pressure scanning valves enhance the completeness of wind tunnel testing across four dimensions: breadth,

depth, efficiency, and reliability.

Spatial Completeness: A Fuller Flow Picture: Instead of sparse approximations, hundreds of measurement points

provide a "high-resolution image" of the pressure field, ensuring subtle structures like small vortices or weak shocks

are captured.

Temporal Completeness: Capturing Transient Phenomena: High-speed acquisition enables use in dynamic tests

(e.g., model oscillation, rapid pitch changes), crucial for studying stability and control. This fills a critical gap left

by traditional methods.

Data Reliability: Boosting Confidence: High-precision sensors and rigorous calibration ensure accuracy and

repeatability. Results from different tests or tunnels become reliably comparable, forming a solid foundation

for major engineering decisions.

Efficiency Completeness: Enabling Comprehensive Parametric Studies: The dramatic efficiency gain allows

engineers to test far more conditions (angles of attack, Mach numbers) and design variants within budget

and time constraints. This ensures a thorough exploration of the design space.

In summary, the pressure scanning valve was a key innovation that propelled wind tunnel testing into the

modern, digital era. By providing massive, synchronized, high-fidelity pressure data, it allows engineers to

probe the essence of complex flows more completely, accurately, and efficiently than ever before, delivering

indispensable support for the safety and performance optimization of critical products.

Copyright © 2009-2025 BM Genuine Sensing Technology (Shanghai)Co.,Ltd. All Rights Reserved.